2004 Mercury 200 Tilt Manual

Tilt and Trim Motor Replacing Power Trim and Tilt Systems When replacing your Power Tilt and Trim Motor, first identify what type of Power Tilt and Trim Motor and Pump you have in your boat. There are two basic types of power Trim and Tilt Systems being used in the recreational Boating industry regardless of weather you have an Outboard or an I/O Sterndrive. Some of the older Power Tilt and Trim Systems used an Electric Tilt Motor in combination with a mechanical lifting device. For example, Volvo Penta used a 12-Volt Power Tilt Motor turning a lifting screw on their older Stern Drives. On older OMC Stern Drives, an electric Motor turned a Worm Gear and incorporated a wet clutch pack to Tilt the drive unit as well as lock it into place.

The Electric Hydraulic power Trim and Tilt System is more common. This type of system is used on Johnson and Evinrude Outboards, Mercruiser Stern Drives, Mercury Outboards and Volvo Penta Stern Drives. This system consists of two major components; the 12 volt electric Motor with a reservoir, and the Hydraulic Pump or Valve Body. Trouble Shooting Your Power Trim and Tilt System When experiencing problems with your power Trim and Tilt System, there are a few easy ways to diagnose just what the problem is.

Generally come in two styles. All use a 12 volt D/C reversing Motor. Some Motors have a two wire connection and some Motors have a three wire connection. All power Trim and Tilt Motors come with one blue wire and one green wire.

The three wire power Trim and Tilt Motors have an additional Black wire as well. The Black wire works as a Ground on power Trim and Tilt Motors that don’t ground thru the case. When the blue wire is energized it raises the Motor or drive unit up. When the green wire is energized it lowers the drive unit down. When having a problem first you need to determine whether your problem is with the power Trim and Tilt Motor or the Hydraulic Pump Valve Body assembly.

If you attempt to raise the Motor or sterndrive to the up or down position and nothing happens, first check to make sure your Battery is charged and switched on if your boat is equipped with a Battery switch. If you hear a slight clicking noise you have power coming from the switch to the solenoid. The next step is to go directly to the Motor and test it there. First, disconnect the power Trim and Tilt Motor. Using a jumper wire, apply 12 volts directly to the blue wire if your engine or drive unit is in the down position. It should raise up at this time.

If it is in the up position, apply power to the green wire reversing the Motor and lowering the unit. If the Motor runs, you may have a problem with a solenoid or lack of voltage coming from the power Trim and Tilt switch to the solenoid. If your power Trim Tilt Motor won’t run after this procedure it is time to replace it. Some replacement will come with a new wiring harness and relay kit to convert your old three wire power Trim and Tilt Motor to a new more powerful two wire Motor. Power Trim and Tilt Pump Problems Tilt and Trim Pump If your power Trim and Trim Motor is working fine but the engine or drive unit won’t stay Trimmed or bleeds down when in the up position, you most likely have a problem with the Hydraulic pump or Valve Body assembly.

In that case it can be removed and rebuilt by a qualified repair facility. Replace the power unit and fill the reservoir with the correct Power Tilt and Trim Fluid per your owner’s manual.

Generally, Transmission fluid is not recommended. It can be hard on some seals due to the high amount of detergents. Most power Trim and Tilt units will purge the air from the system just by running the engine or sterndrive up and down two or three times with the vent plug loose. Bottom line If the motor works in one direction there is nothing wrong with the motor. The most common issue is a bad solenoid on a 3-wire motor or a bad relay on 2- wire motor. If the motor runs but won’t raise or lower the drive or outboard engine, check the fluid level first. If the level is full there is a problem with the pump.

Makes a direct replacement for many models (in some cases your only option is to have the old pump rebuilt). Hope this helps you repair your tilt/trim system so you can get out and enjoy your boat. If you need any parts, visit us at, or call toll free 1-800-998-9508. Article by: Michael Weller Go2marine.com Sales Manager Engine, Propulsion and Steering Systems Specialist.

Elbert Hodges May 12th, 2013 I have a 2001 Yamaha F80 TLRZ After having sat unused for about four months, I am unable to trim/tilt the engine. I hear a clicking noise when I attempt to raise the engine, but it does not move. In order to troubleshoot the problem, the manual instructs to loosen the manual valve screw all the way until it stops, then put the engine in the desired position and tighten the screw. After loosening the valve screw, I am unable to raise the engine. So far, even with the help of a second person, I have been unable to raise the engine. If I can raise the engine, I will be able to troubleshoot the trim/tilt system.

Any suggestions how to raise the engine??? Chuck mahoney May 12th, 2013 I have a 90 TLRV Yamaha with a 6H1 power tilt trim system I am experiencing no down pressure. It started leaking fluid one day so I ordered seals and o rings for it took it out worked a couple of days and stopped going down.then I replaced hydraulic pump, sub valves, and all relief valve seats and springs since and every o ring and seal again. Still have the same problem could it be a worn or sticking shuttle valve? I have hydraulic experience I work on tractor hydraulics and this seemed to be a simple system. I have excellent up pressure and no down pressure.tilt will start down and stop half way down then pull trim cylinders in and then tilt extends back up please help. Travis May 7th, 2013 I have a ’99 Stratos 21SS Extreme with a Johnson 225 H.O.

The trim will start going down while I’m running down the lake and won’t stop unless I hold down the trim up button. As soon as I let off the trim up button it continues to trim down. The motor does not go up while I’m holding the trim up button.

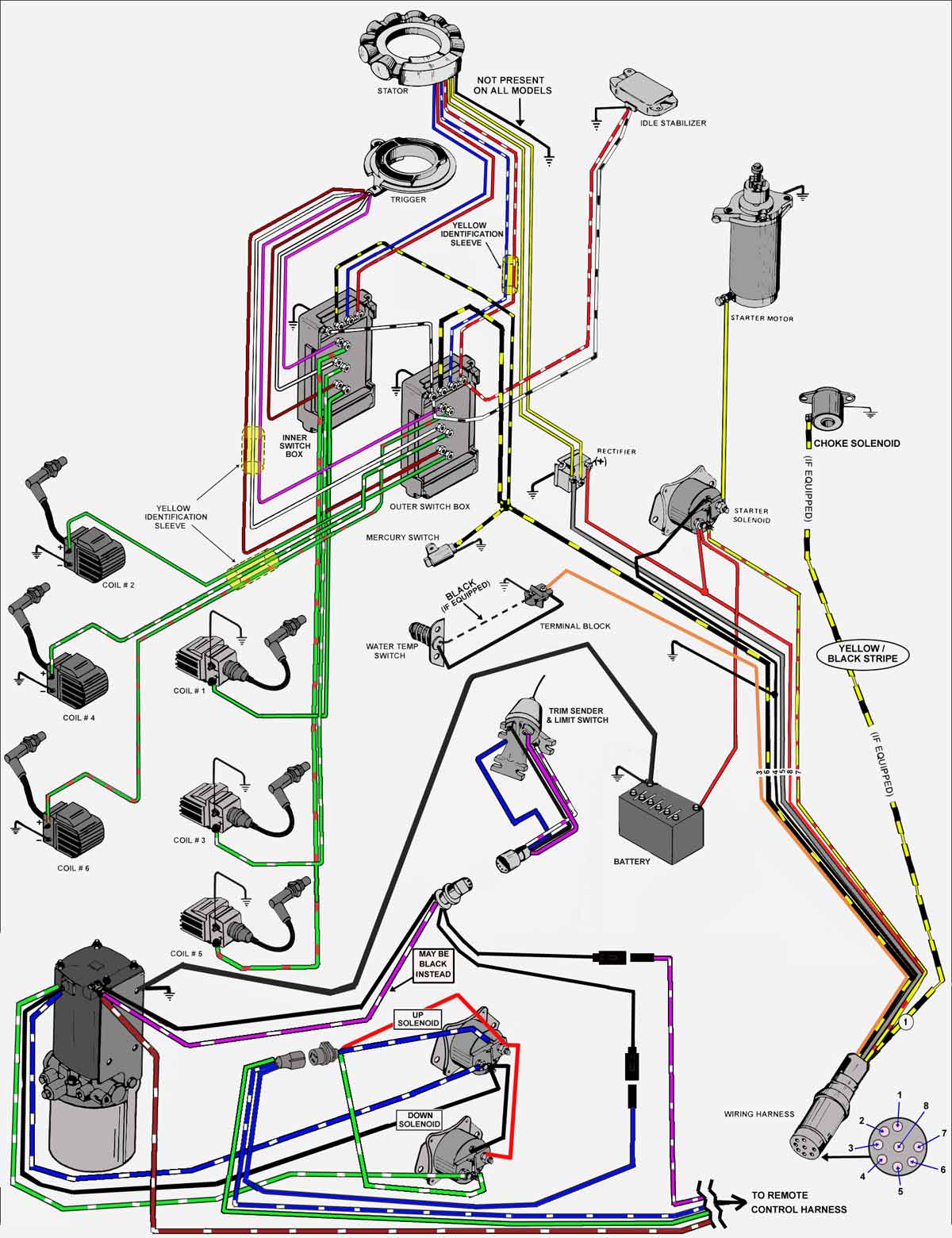

Mercury Tilt And Trim Diagram

The only way to get it to stop is to unhook the battery cable. It will be fine for about 1-2 mins and then it’ll start trimming down again. It did it again once I got the boat out of the water too.

Mercury 200 Outboard Manual

It was raining all day while I was fishing and didn’t start doing it until about 4 hrs on the water. Thought maybe the rain had something to do with it but not sure. Any help would be greatly appreciated.

Sandy March 22nd, 2013 I have a ’98 50 hp 4 stroke Yamaha. The tilt motor had hyd oil in it around the armature and brushes which caused the brushes to seize, etc. My question is, it normal for there to be oil in the sump where the gear pump is (directly below the motor)?

Was the leak into the motor just from worn out seals on the motor output shaft or is there another problem? There was not much oil in the motor, just enough to cover the armature, not up to the windings. I’ve never had one apart before. Thanks for your help. ERIC March 12th, 2013 i have a 73 mercury motor w/hydraulic tilt and trim. It has been siiting for a bit and last time i had it out on the water. Coming in to trailer itthe tilt wouldnt raise the motor.after insepecting it i found one of the fluid lines loose.after i tightened it up i was able to traise the motor.now after sitting when testing the motor i took off the motor support and the motor lowered on its own.so i then tried raising it with the tilt and trim.however the motor didnt move either way.im thinking its probably full of air and low on fluid since when i tried to raise the motor manually it wouldnt budge.can you offer any tips and maybe tell me how to check the fluid and its capacity?